Burgess Falls Dam is reinforced with rock anchors to protect natural area

The State of Tennessee has stabilized an 80-year-old dam to secure its integrity and keep years of sediment upstream.

Burgess Falls Dam is a gravity concrete structure approximately 340 feet long and nearly 40 feet tall with seven uncontrolled spillway bays. Located on Falling Water River at Burgess Falls State Natural Area in Putnam County, Tenn., the dam did not meet mandated safety criteria.

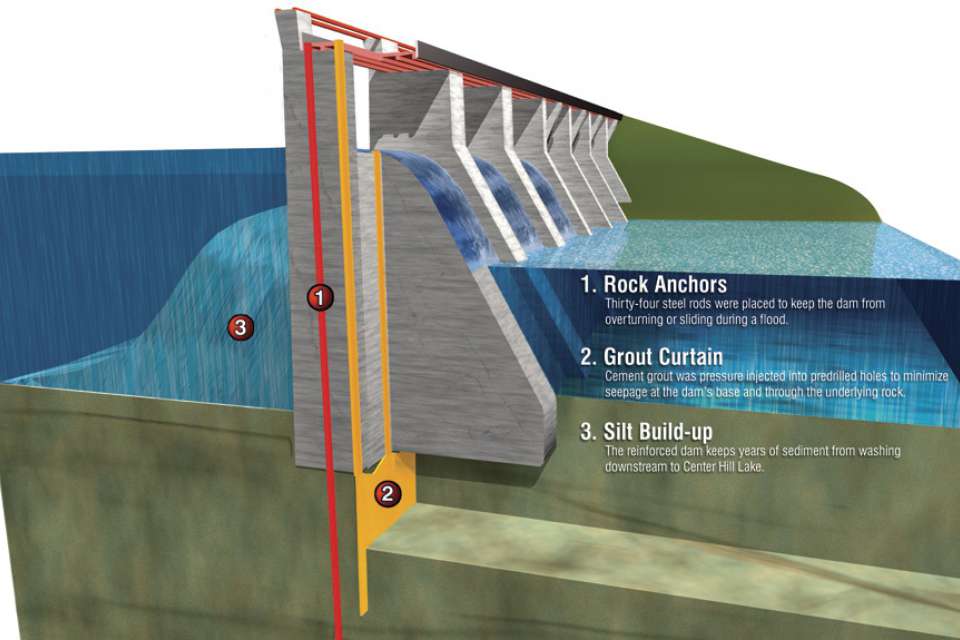

"The State of Tennessee needed a stabilization method to keep the dam from overturning or sliding during a heavy flood," said Garver Project Engineer Billy Rider. "The dam also required repairs to keep water from seeping through cracks in its concrete."

The dam stabilization project was a long process with many starts and stops, said Safe Dams Chief Lyle Bentley of the Tennessee Department of Environment and Conservation. However, its ultimate completion has kept two of the area's centerpieces intact for years to come—Burgess Falls Dam and Center Hill Lake.

"The area above the dam is badly silted in, which is part of the reason why the dam had to be reinforced," said Bentley. "We wanted to make sure the sediment stayed behind the dam and didn't move downstream to Center Hill Lake. We had to strengthen the dam before that happened, and removing the structure wasn't an option."

In 1996, the State of Tennessee opened the dam's sluice gate to allow water to drain freely through the barrier. However, officials soon discovered that this could cause environmental issues. Dropping the water level would adversely affect the wetland areas upstream and wash years of sediment behind the dam down into Center Hill Lake. The U.S. Army Corps of Engineers investigated the dam's long-term stability, and after evaluating water and silt loads, the Corps concluded that the dam did not meet minimum safety criteria for all load cases. The Corps ultimately determined that rock anchors would adequately stabilize the dam and keep the sediment out of Center Hill Lake.

Garver prepared an engineer's report in 1999 to review corrective methods, prepare cost options and recommend various stabilization alternatives. However, because the construction budget was initially limited to $645,000, the design and construction phases were halted until additional funding became available.

In 2007, the State of Tennessee rehired Garver to prepare structural plans and specifications.

"Garver took over the 30-percent design plans and carried the project through to completion," said Garver Project Leader Chris Wilbourn. "Initially, Garver performed hydraulic and hydrology studies to determine current probable water surface elevations. A preliminary structural evaluation also was conducted."

Garver confirmed that Burgess Falls Dam would meet all of the Corps' safety factors by installing rock anchors throughout the structure and by constructing a grout curtain to minimize seepage at the dam's base and through the underlying rock strata. In addition to shoring up the dam, this option retained the historic structure's appearance.

"Placing rock anchors is like installing rebar after the fact," Rider said. "You're drilling a hole through the dam's concrete into the rock foundation and inserting a post-tensioned bolt to strengthen the structure."

Thirty-four 60-plus-foot-long, 1 ¾-inch diameter, grade 150 ksi steel bars were embedded into the dam. To ease installation, drilling operations were conducted from the roadway that runs along the top of the dam, and the anchors were inserted through the piers and dam into the rock strata.

To create the grout curtain, holes were drilled into the concrete and Portland cement grout was pressure injected through the grooves into the dam and underlying rock strata. The grout fills any cracks, voids or separation in the rock foundation and dam, creating a solid, continuous wall.

The $1.4 million project was completed in October and effectively brought the dam's stability up to Tennessee Safe Dam Standards.

Share this article