Updated arc flash codes help maintain airport compliance

Northwest Arkansas Regional Airport (XNA) has experienced significant growth in the past decade and has modified and expanded its electrical systems to keep pace. Airport officials recently sought Garver's professional services to ensure that their electrical systems are code compliant.

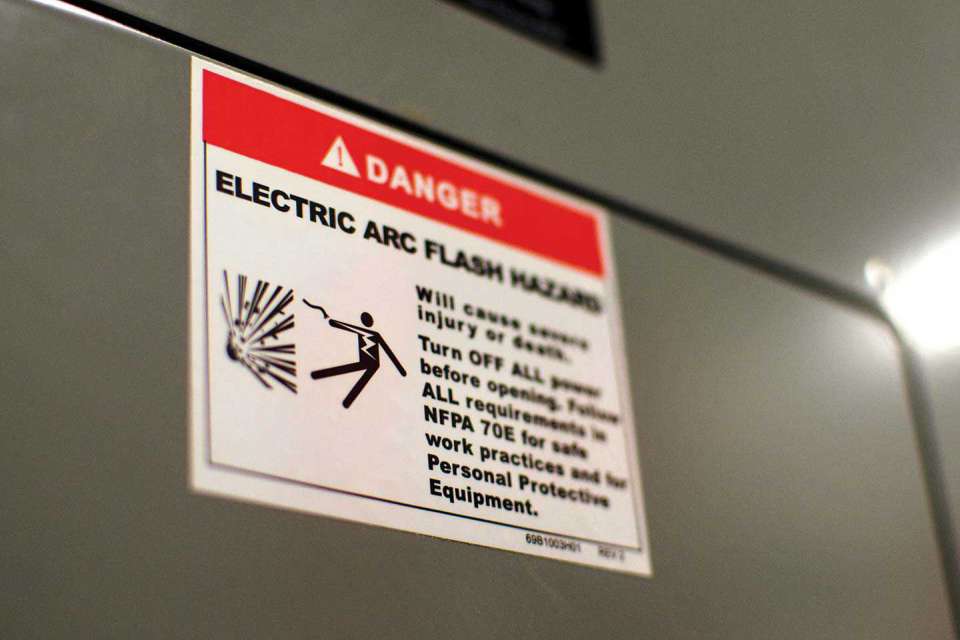

The 2012 National Fire Protection Association (NFPA) 70E (Electrical Safety in the Workplace) and the 2011 National Electrical Code (NEC) detail safety labeling on major electrical components, including arc flash hazard warning labels. The labeling is a safety protocol that alerts electricians and qualified persons to electrical risks and the proper personal protective equipment (PPE) that must be worn when working on energized equipment.

An arc flash is an electrical explosion that causes intense heat up to 35,000 degrees Fahrenheit. It results when high-energy components are shorted together. This can occur from exposed live conductors, fatigued breakers, defective equipment or by dropping a tool during a maintenance procedure or inspection.

"At XNA, we make every effort to stay on top of any new rule, regulation or code change," said Airport Director Kelly Johnson. "Being compliant with code is important for many reasons, including the liability that could result from an arc flash situation. More important, however, is the protection and safety of the public, our tenants and our employees."

The airport requested Garver's expertise to ensure a safe workplace by performing an arc flash analysis, an electrical code compliance study and an overcurrent protection coordination study.

"Garver was selected based on the strength of their electrical engineering staff coupled with their northwest Arkansas office location and previous strong performance in meeting schedules and budgets on XNA projects," Johnson said.

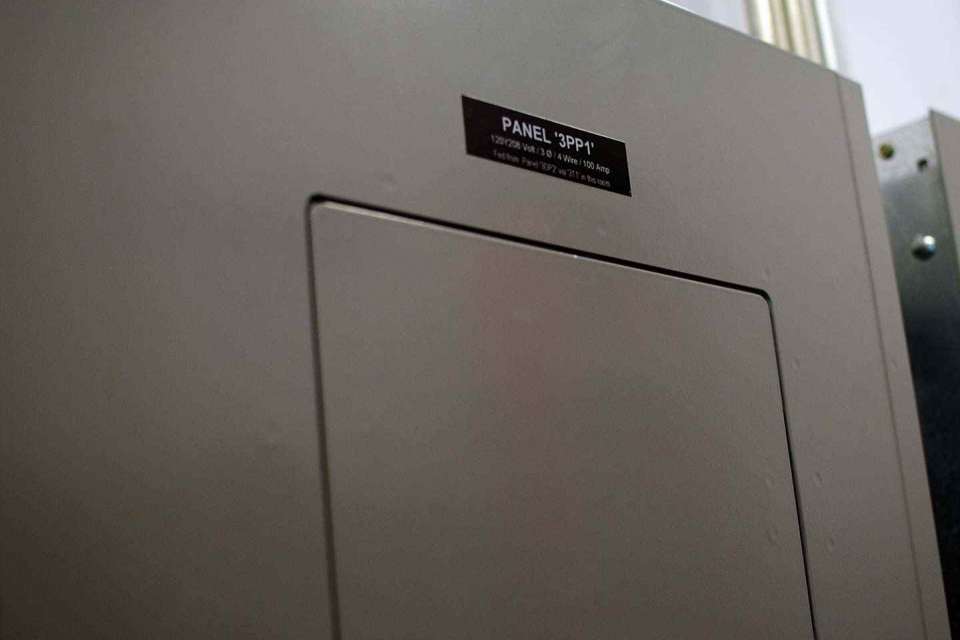

Garver conducted a three-week site investigation led by a team of electrical engineers. After researching the airport's as-built construction drawings and completing site investigations, Garver analyzed the data to determine each electrical panel's unique arc flash hazard analysis (as required by NFPA 70E). Afterward, Garver installed labels with detailed information, provided updated single-line diagrams and assisted the airport in adjusting the electronic circuit breakers.

"Garver was very thorough with the analysis, which gives us greater knowledge of potential hazards the airport might face while maintaining or adding to our electrical system," said XNA Facilities Manager Steve Keith. "We also now have updated information on the proper personal protective equipment needed to work on or near our electrical equipment."

Concurrent with the site investigations, Garver reviewed the terminal and airfield electrical vault to identify code-related system deficiencies. As a trained electrician, Garver used thermographic imagery to observe heat signatures emitted by electrical components. Using thermographic imagery can help discover loose, failing or overloaded parts.

Federal law requires that employees de-energize and "make safe" electrical equipment before performing work. If de-energizing the equipment introduces additional hazards or is infeasible, then the employee must wear the appropriate PPE. The correct PPE is determined through an arc flash hazard analysis.

"There are important electrical code requirements that people need to know about," said Garver Project Leader Keith Tencleve, PE. "XNA is a prime example of an airport proactively pursuing the safety and welfare of its maintenance staff, as well as contractors working on electrical systems. This project significantly improved the electrical system's overall function while also identifying areas where the system does not meet current code requirements."

Safety Protocol Checklist

Is your electrical system compliant with the latest codes? * Use this checklist as a guide to keep your system up to date.

- Perform an arc flash analysis every five years or after major modifications or renovations.

- Maintain an up-to-date single-line diagram for the facility electrical system.

- Label the service panel with fault current per utility data and short circuit study.

- Include proper labeling and signage on ALL electrical panels and equipment: - NEC-required equipment identification - Conductor color identification - Arc flash boundary/hazard/PPE warning signs - Voltage system signs

- Provide personal protective equipment for your electricians.

- Provide equipment-use training for your electricians and staff.

- Have a safety plan that complies with OSHA, the 2012 NFPA 70E and the 2011 NEC.

* See the 2011 NEC Section 110.16 (arc flash), 110.10 and 240.12 (coordination study), the NFPA 70E, Article 130.5 (C) (arc flash) and the OSHA regulation §1910.335 (arc flash).

Share this article