Fast-Track Lighting Upgrades

With one of three runways already closed for construction, replacing the Runway 4R-22L centerline lights was a critical task considering it would leave the airport with one open runway. Garver was entrusted to complete the repairs under an ambitious timeline needed to minimize impact on airport operations.

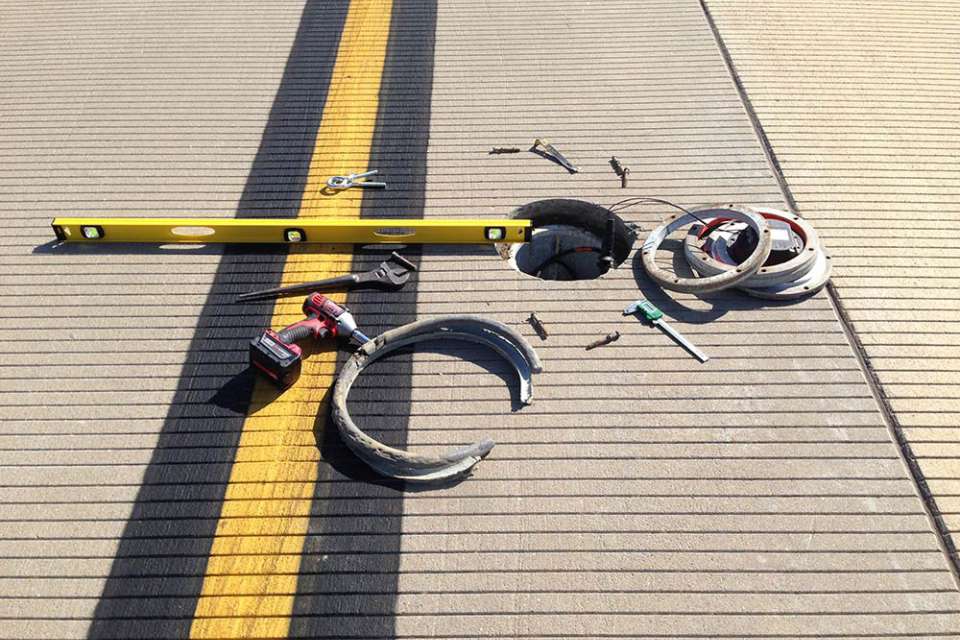

"The key to our centerline lighting project was preplanning and creative engineering," said Thomas Clarke, the airport's Director of Properties, Planning and Development. "Garver designed a rig to custom measure each light and calculate the custom shims required at each location. They then worked with the contractor to explain and enhance the process during construction."

The project also included full-depth runway and taxiway pavement repair, 165,000 linear feet of concrete pavement joint resealing, 52,000 linear feet of airfield lighting cable, and new pavement markings. An "Overcome All" clause allowing work on nights, weekends, and holidays enabled project completion in 55 days, well under the 75-day maximum.

The new LED fixtures last 150,000 hours compared to the old 1,000-hour incandescents, and were attached to the existing base using new techniques that require a higher bolt torque. The LED fixtures dropped the lighting load from 20 kW to 10, leading to a 50-percent energy savings. All work was completed within the schedule and $300,000 under budget.

"By replacing the old incandescent lights with LED lights, the airport significantly upgraded the quality and lifespans of its lighting systems," said Eric Farmer, Garver Senior Project Manager. "Garver's ongoing relationship with the airport and the FAA made it so improving the safety of the pilots and passengers who use one of the state's busiest runways went smoothly and stayed under budget."

Share this article