Tuscumbia Membrane Softening WTP Pilot

Garver’s state-of-the-art membrane process enhanced water treatment, minimized DBP formation, and provided safer, cleaner water to the community

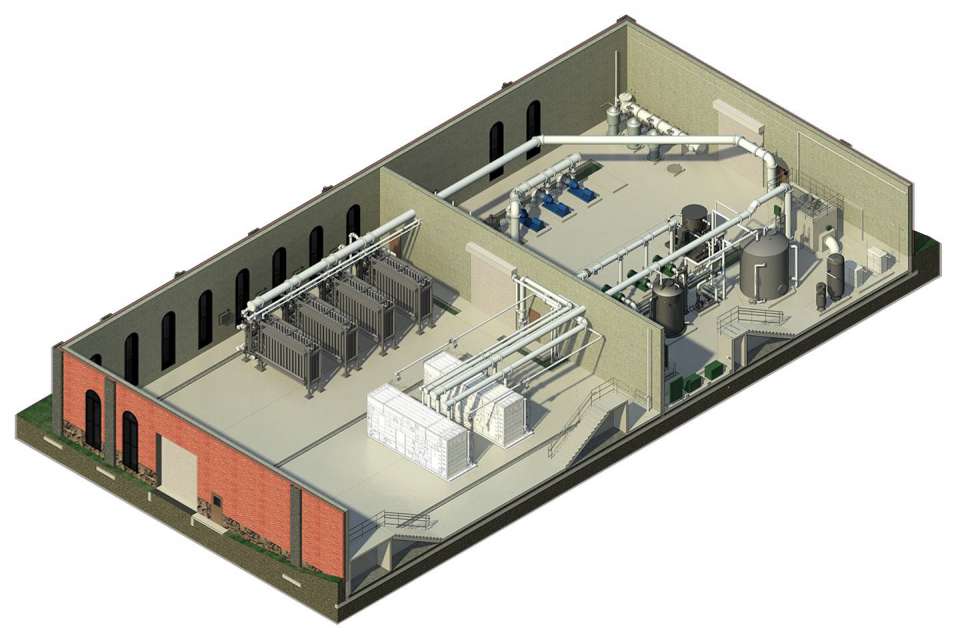

Garver used building information modeling (BIM) to enhance design efforts and coordination, as well as public communications and awareness, for a new water treatment plant in historic Tuscumbia, Alabama. The new plant includes a state-of-the-art, series membrane process - ultrafiltration (UF) followed by reverse osmosis (RO) – and provides safer, softer water to the residents of Tuscumbia.

We designed the treatment train to include series UF and RO membrane processes, which enhanced treated water quality through better filtration, minimized DBP formation potential through TOC reduction, enabled superior pathogen removal, and targeted total hardness levels of approximately 120-mg/L (as CaCO3) - a reduction of about 50% over raw water concentrations. The RO process transformed hard water by removing certain ions via molecular weight exclusion – ultimately providing highly desired, softer water to customers.

Due to intricacies of the membrane systems and ancillary equipment, as well as the need for tight coordination between design disciplines, our team leveraged the capabilities of BIM for design of the new membrane and administration facility.

This decision not only increased design efficiency and construction document accuracy, but it also provided a value-added service for the City and its residents. Because Tuscumbia's new water treatment plant is situated near Big Spring Park - a historic site enhanced by residents with a waterfall, fountains, and a laser light show - communicating aesthetic features of the new plant with City officials and constituents was critically important. By capitalizing on the benefits of BIM, we provided rapid prototyping and realistic rendering, which proved very effective as a communication tool throughout the design process.

The total project included new raw water pumping, pretreatment basins, UF and RO membranes, disinfection, and high-service pumping, as well as new chemical storage and feed, laboratory, and administrative facilities.

Share this article