The Phosphorus Fix

WWTP is prepared to meet anticipated nutrient discharge limits

By implementing the first phase of an enhanced nutrient removal program at its wastewater treatment plant on Sager Creek, the City of Siloam Springs, Ark. is well on its way to meeting unprecedented effluent phosphorus limits targeted for 2012.

Next year, the Environmental Protection Agency will consider setting the phosphorus discharge limit at 0.037 milligrams per liter (mg/L) for the Illinois River and its tributaries. However, the city adopted an interim phosphorus limit of 1.0 mg/L and a nitrate limit of 10 mg/L. As part of a plant upgrade to increase treatment capacity, the facility has incorporated a custom-designed biological nutrient removal (BNR) process without filtration. Now operational, the new bioreactor is producing a discharge phosphorus of less than 0.4 mg/L and nitrate less than 10 mg/L.

To achieve this level of performance, the city partnered with Garver to develop, design and implement the enhanced nutrient removal program, which reduces the phosphorus levels in three process phases. The project's first two phases are now online and improve the liquid process treatment train through BNR and chemical nutrient removal (CNR).

The BNR treatment process involves a combination of anaerobic/anoxic/aerobic zones to target effluent phosphorus and nitrate concentrations. Although the new BNR technology has achieved phosphorus nutrient removal as low as 0.4 mg/L at the treatment plant, its marriage to the CNR process will help the plant achieve phosphorus levels another magnitude lower. The CNR process chemically enhances phosphorus removal capabilities through precipitation.

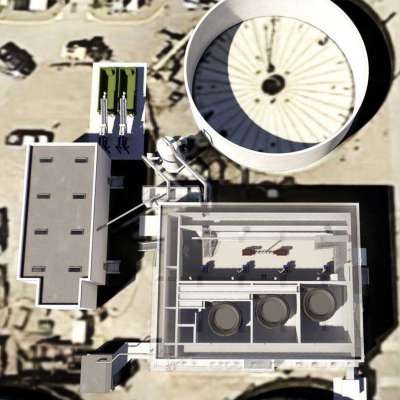

The completed liquid process treatment upgrades include minor modifications to the headworks facility and primary clarifiers, new BNR and CNR processes followed by conventional clarification, minor modifications to re-aeration and disinfection processes, and odor control. Solids train improvements primarily consist of new primary sludge thickening and fermentation, new Waste Activated Sludge thickening, new aerobic digestion and a new solids dewatering facility.

To meet a potential future 0.037 mg/L phosphorus mandate, the treatment plant is designed to integrate membrane biological reactor (MBR) technology, which provides a physical barrier against phosphorus by using membrane media. Prior to full-scale design, Garver performed a pilot study to verify MBR performance at the plant. Two parallel pilot-scale MBR process trains were demonstrated over a six-week period. The data revealed that MBR technology, in combination with BNR and CNR, can consistently produce effluent with phosphorus levels at 0.025 mg/L, well below any reported ultimate final discharge limits.

Together, the custom-designed nutrient reduction program and biosolids improvements have increased treatment performance, reliability and operational flexibility for the city.

Share this article