WW Reuse: The New Commodity

Fort Sill uses wastewater recycling system to condition buildings, supply cooling towers and prepare for future irrigation

An advanced recycling method is repurposing wastewater to reduce potable water usage and improve energy efficiency at Fort Sill in Lawton, Okla.

The Fort Sill wastewater treatment plant has adopted a reuse system that replaces on-site potable water usage with high-quality wastewater effluent. The recycling distribution network gives Fort Sill the ability to use the treated wastewater in its energy plant's cooling towers and for geothermal heat pumps to condition buildings.

"Under a typical water rate structure, a project of this type has the potential to save the utility between $200,000 and $300,000 a year," said Garver Treatment Plant Operations Specialist Michael Graves. "When recycled water leaves the treatment plant and picks up additional users, it becomes a new commodity while reducing potable water usage and costs."

Reuse Regulations

At the time Garver began working on the design, Oklahoma did not have specific standards regulating the design and construction of a wastewater reuse system. Although there are sites in Oklahoma that have received wastewater reuse approval, there weren't any regulated design guidelines.

"We knew the quantity of reuse water that Fort Sill wanted, and we knew what the water quality objectives were," Graves said. "After determining the volumes needed, we worked to make sure the reuse infrastructure was capable of meeting water quality requirements and Fort Sill's needed demand."

From the beginning, Garver closely worked with the Oklahoma Department of Environmental Quality to develop the project's elements. There were also meetings as the project progressed through the 30, 65 and 95 percent complete stages.

Multiple agencies were involved throughout the project's design and construction, including the U.S. Army Corps of Engineers, Fort Sill Department of Public Works, site owner and operator American Water, project leader The Ross Group, and various subconsultants. The project was funded through the American Recovery and Reinvestment Act, which also required various stipulations be met to receive the funds.

Distribution System

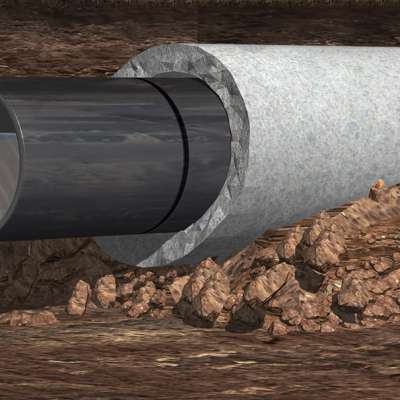

The Fort Sill wastewater treatment plant produces high-quality effluent. Its treatment process includes clarification, activated sludge, filtration and UV disinfection with re-aeration processes. To move the treated water around Fort Sill, Garver designed a recycling distribution network that includes a chlorination chemical treatment system, a pump station, and underground supply and return piping.

"After the water has made it through the last treatment process, a 700,000-gallons-per-day pump station conveys the water into the reuse piping network instead of being discharged to East Cache Creek," Graves said.

When the recycled water enters the piping network's horizontal loop, it is dosed with chlorine by a liquid solution feed diffused into the line. The chlorine minimizes buildup of organics inside the pipes, and the dosage is automatically maintained by a chlorine residual analyzer.

Planned expansion of the reclaimed water network required Garver to design the infrastructure to operate between 30 gallons per minute and 350 gallons per minute. Buried 6 feet underground, the horizontal loop's supply line is 8 inches in diameter, and the return piping is 1.5 inches in diameter.

"We designed the system to accommodate much larger future flow rates, yet the system had to be able to meet existing flow conditions as well," Graves said. "That was a challenge because the system's excess future capacity can create some difficult hydraulic operations until the future demand is achieved. The system currently operates at approximately 50,400 gallons per day, and in the future, it will be capable of 700,000 gallons per day."

The recycled water pump station includes variable frequency drives for variable flow, and it automatically refills the ground loop when pressure drops below a predefined value during cooling tower operation. The pumps include pressure controls to maintain the predefined pressure. Blowoff valves were added to counter extremely slow flows in supply and return lines.

Benefits

Once in the network, the recycled water branches off the horizontal loop and feeds the Central Energy Plant Building 5900's four-cell cooling tower.

"Fort Sill had been paying for potable water for use in its cooling towers," Graves said. "To feed the cooling towers with reuse water, it had to have the right chemical balance and right flow rates to allow the system operator to disconnect from the potable water system."

When the recycled water reaches the distribution system's return loop, it feeds geothermal units in the administrative office.

"Geothermal heat pumps were installed in the break room, SCADA room, office and maintenance room," said Garver Project Leader Shane Smith, PE. "The recycled water is used as a ground-source heat-transfer medium to operate the heat pumps, which supplements those rooms' conventional heating and cooling systems."

There are also plans to use the recycled water to irrigate the Fort Sill Officer's Club Golf Course and polo fields, as well as replace potable water usage when washing down Fort Sill's operations equipment.

"Clients can get a big bang for their buck when recycled water becomes a commodity," Graves said. "At Fort Sill, those potential users are the energy plant, other chilled water or cooling tower operations, and irrigation for event fields. Contractors can even access it for dust control during construction activities."

Share this article