More than Meets the Eye

Added pavement layer will keep Oklahoma airport looking new for years to come

Maybe to you the word innovation invokes ideas of computers that fit in your pocket, or sunglasses that possess the ability to take photographs. To Garver, innovation means finding room for improvement in places no one expects, and that's exactly what happened in Sand Springs, Okla., where Garver recently completed runway overlay construction at William R. Pogue Municipal Airport.

"No one can see the innovations by standing there looking at the pavement, but that doesn't mean the innovations aren't there," said Project Leader Kelly Fincannon, PE. "And that doesn't mean any changes at the airport can't be seen."

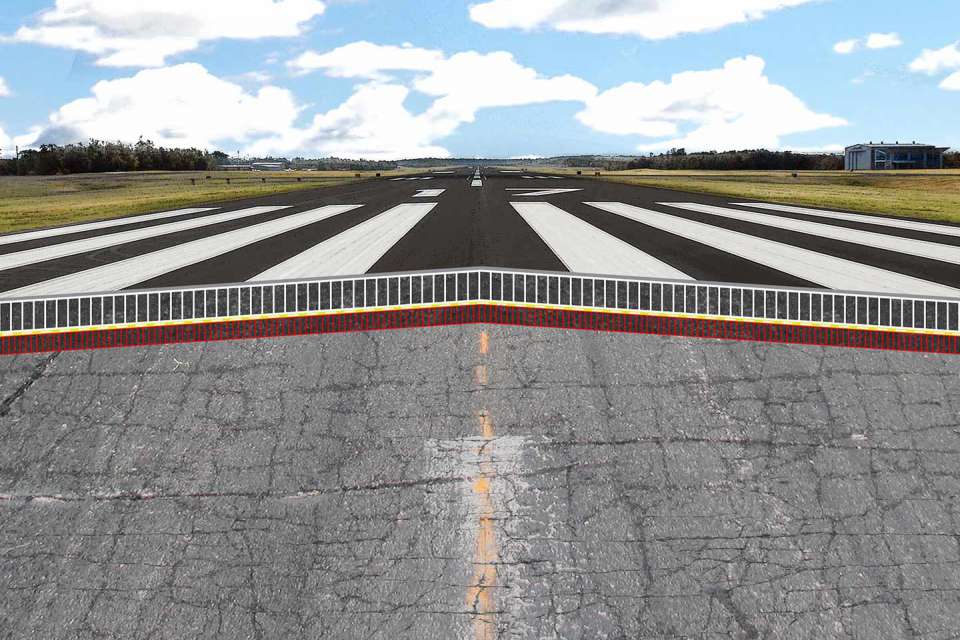

"Pilots have reported clearly seeing the airport from 15 miles out," said Pogue Airport Manager Ken Madison, "due to the new white marking on the new black pavement."

By providing several additive alternates in the bid package, Garver project leaders obtained $169,000 in additional funding to seal all the pavements at the airport when money became available from the Oklahoma Aeronautics Commission (OAC). Those funds allowed Garver to experiment with the seal coat used on the 43-year-old asphalt at Pogue Airport, which was in bad need of repair. Garver's phased approach only required the airport to close for seven days while the seal coat was installed on the runway.

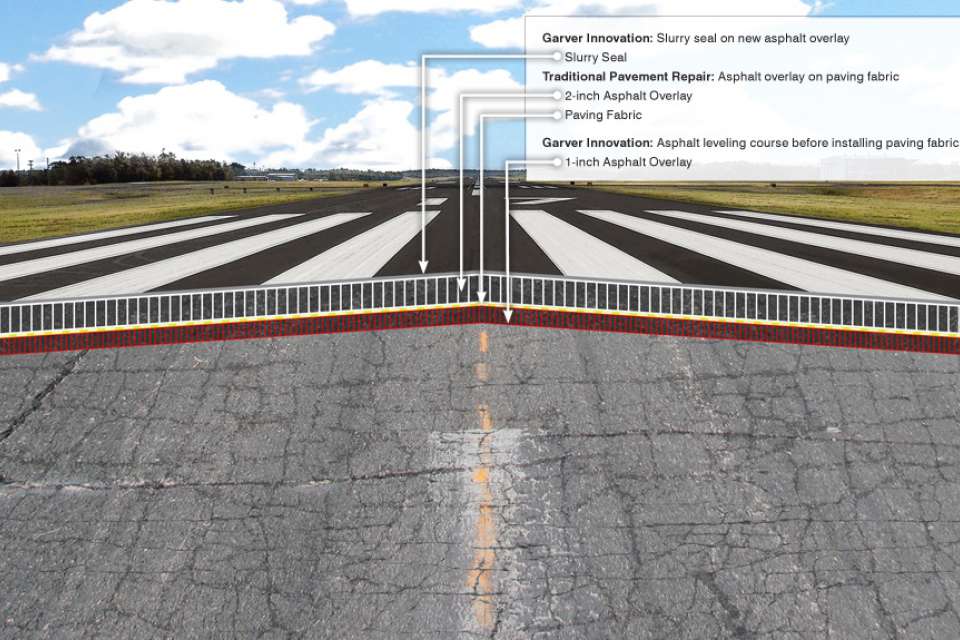

After filling the wide cracks in the pavement with emulsified asphalt and aggregate, the normal approach to an overlay would've been to place a high-quality non-woven fiberglass/polyester interlayer paving mat (paving fabric) before layering on the asphalt overlay, which retards reflective cracks that will creep up from the old underlying pavement. Garver improved on this formula by adding a leveling course of asphalt underneath the paving fabric.

"Placing a thin leveling course before placing the paving fabric allows the paving fabric to hold together a new, tight asphalt rather than the wide cracks underneath," said Fincannon.

The project called for every stretch of airfield pavement to be rehabilitated at the same time. The runway was overlaid with three inches of new asphalt. Both parallel taxiways, all connector taxiways, all hangar access taxiways, both the east and west aircraft parking aprons were all crack-sealed and then given a seal coat of thermoplastic coal tar emulsion that will seal out the elements and extend the life expectancy of the pavement.

Raising the Bar

The OAC performs a regular pavement condition index (PCI) inspection on runways throughout the state, which rates the general condition of the pavement and issues the results as a numerical value—zero (poor) to 100 (perfect). The OAC last rated Pogue Airport in June 2009, and issued the pavement a 29. During the final inspection of the completed $3.3 million overlay project, the OAC stated that the pavement at Pogue Airport would now be rated a PCI of 100—a perfect score.

Share this article