A freeway widening project in Tulsa, Okla. is providing traffic-weary commuters with much needed relief.

"Traffic is no longer congested during morning and evening commutes," said Oklahoma Department of Transportation Division 8 Assistant Engineer Mark Zishka, PE. "The additional lanes greatly enhance the U.S. 169 corridor."

More than 65,000 vehicles use U.S. 169 every day, and transportation officials initiated improvements to increase capacity and provide a safer artery between Tulsa and Owasso, Okla. The ODOT project recently widened the urban freeway from four to six lanes, pinpointing a 5-mile stretch beginning at Interstate 244 and heading north to 56th Street North.

Garver's consultant services included a preliminary engineering and traffic analysis report, design, and plan production for roadway, bridge, drainage, traffic and construction sequencing.

"This project was designed under an expedited schedule, and there were several difficult design constraints that had to be addressed and overcome," said ODOT Division 4 Engineer Paul Green, PE. "It was imperative that an excellent design with well thought out construction phasing and sequencing be achieved for this high-capacity corridor."

Inside the Median

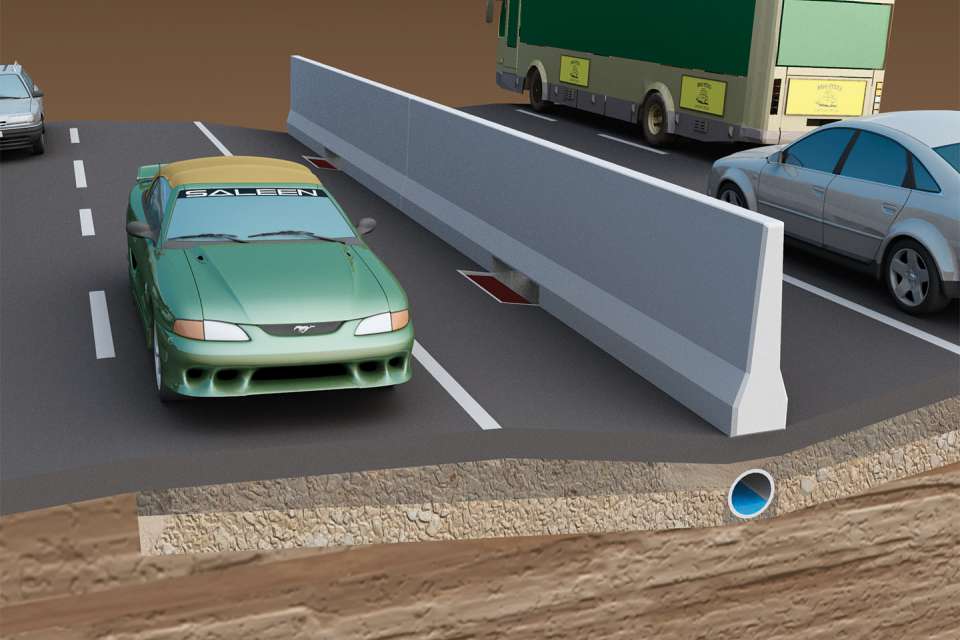

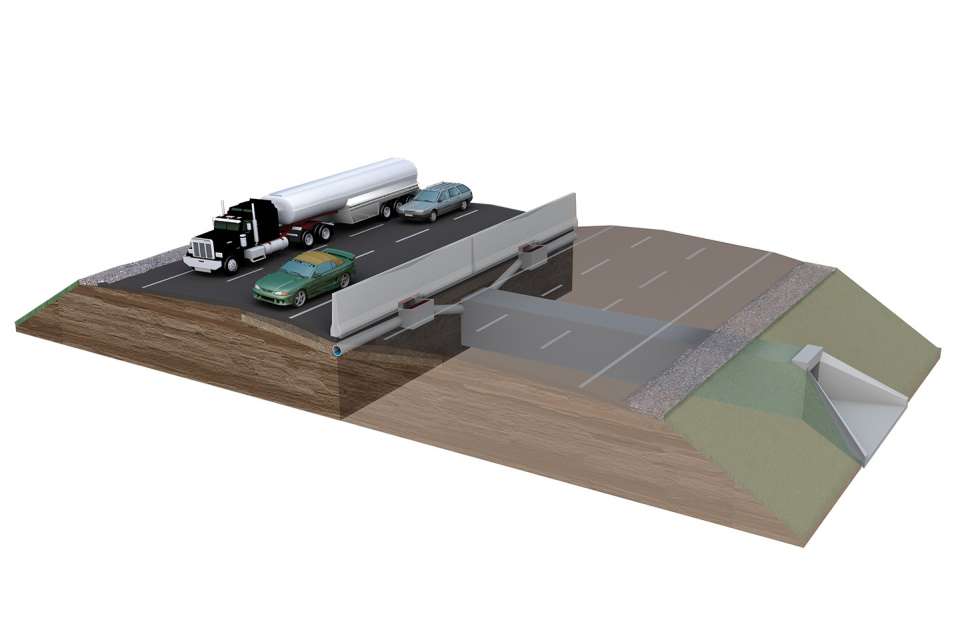

Because U.S. 169 is in an urban area, the project faced right-of-way constraints and utility relocations and could have impacted multiple interchanges. However, to keep costs down and shorten the construction schedule, Garver worked with ODOT to position the new lanes inside the median's footprint rather than expanding out.

"This cost-effective method provided added capacity," said Garver Project Manager Brent Schniers, PE. "By designing the new lanes inside the median, it eliminated the need to acquire additional right-of-way, limited the impact to multiple interchanges and avoided existing utilities."

Garver provided a preliminary engineering report that analyzed various widening options to upgrade the existing 40-foot-wide grass median to a divided roadway with a concrete median barrier. Because of the narrow median, widening options were limited to non-standard lane and shoulder widths. Garver studied multiple options that both improved safety and accounted for the width limitations. Garver and ODOT then selected the best widening method, which balanced modified lane and shoulder widths to improve safety and capacity.

Drainage Design

To keep stormwater from ponding along the inside median shoulders, Garver designed a unique drainage profile to maintain positive flow within the median.

"The existing roadway profile was flat in areas, so we provided a design that varied the shoulders' slopes, which created the 'peaks and valleys' that lead to the median inlets," said Garver Roadway Designer Kevin Moore, PE. "And because of limestone within the area, we had to keep the storm sewer as shallow as possible, which made it a challenge to ensure positive drainage."

The shallow bedrock depth presented constructability concerns for trenching storm sewer pipes. Garver's construction plans included a geotechnical profile that showed contractors the approximate rock line. Borings were taken every 500 feet, and the information assisted contractors in providing more accurate cost bids.

"The geotechnical testing provided the contractor with more comfort in appropriately bidding the project. They weren't surprised by the soil conditions," Schniers said. "Contractors were able to make competitive bids, which in turn benefited ODOT and the project's cost."

In addition, the stormwater outlet pipes were bored under the freeway to maintain four lanes of traffic during construction.

Pine Street Bridge

A portion of the freeway crosses over Pine Street, and the dual bridges required superstructure improvements to add new lanes and substructure work to correct structural deficiencies. To complicate matters, the underside of the bridge's deck had sustained numerous collisions from tractor trailers traveling below on Pine Street.

"The bridge structures had a relatively low vertical clearance, and with the industrial area surrounding the bridges, there were several hits. And actually, there was a hit on that bridge during the design process," said Garver Bridge Designer Jason Langhammer, PE. "We took a hard look at the bridge to design special beams that would improve Pine Street's vertical clearance."

In widening the bridge decks for a third lane and outside shoulders, the freeway's cross slope would have lowered the beam elevations, reducing the Pine Street vertical clearance even more. To compensate, Garver utilized a shallower beam depth to actually increase the original vertical clearance by 6 inches.

"The shallower beams provided us with the right solution to correct the problem," Langhammer said. "This bridge project really had a lot of different design aspects beyond simply rehabilitating the existing structure. In fact, after construction had started, field discoveries determined that the existing bridge abutments also needed modifications."

There were no piles underneath one of the abutments, and Garver worked quickly to resolve the issue and allow construction to continue. "With the additional dead and live loads that were being added to the substructure, ODOT immediately came to us, and within a week, we'd designed a supplemental footing to add to the abutment," Langhammer said.

Construction is now substantially complete, the lanes are open and the improved freeway's greater capacity is encouraging traffic to flow more smoothly. A final wearing surface, which will improve roadway surface drainage and reduce pavement spray back during rain, will be added when the temperature warms.

"This project proved to be a great success for all parties involved and one that will serve the citizens of Oklahoma for many years to come," Green said.

Share this article